Ultraprecise 3D printing technology is a key enabler for manufacturing precision biomedical and photonic devices. However, the existing printing technology is limited by its low efficiency and high cost. The conventional nanoscale 3D printing technology, i.e., two-photon polymerisation (TPP), operates in a point-by-point scanning fashion. As such, even a centimeter-sized object can take several days to weeks to fabricate. The process is time-consuming and expensive, which prevents practical and industrial applications. To increase speed, the resolution of the finished product is often sacrificed.

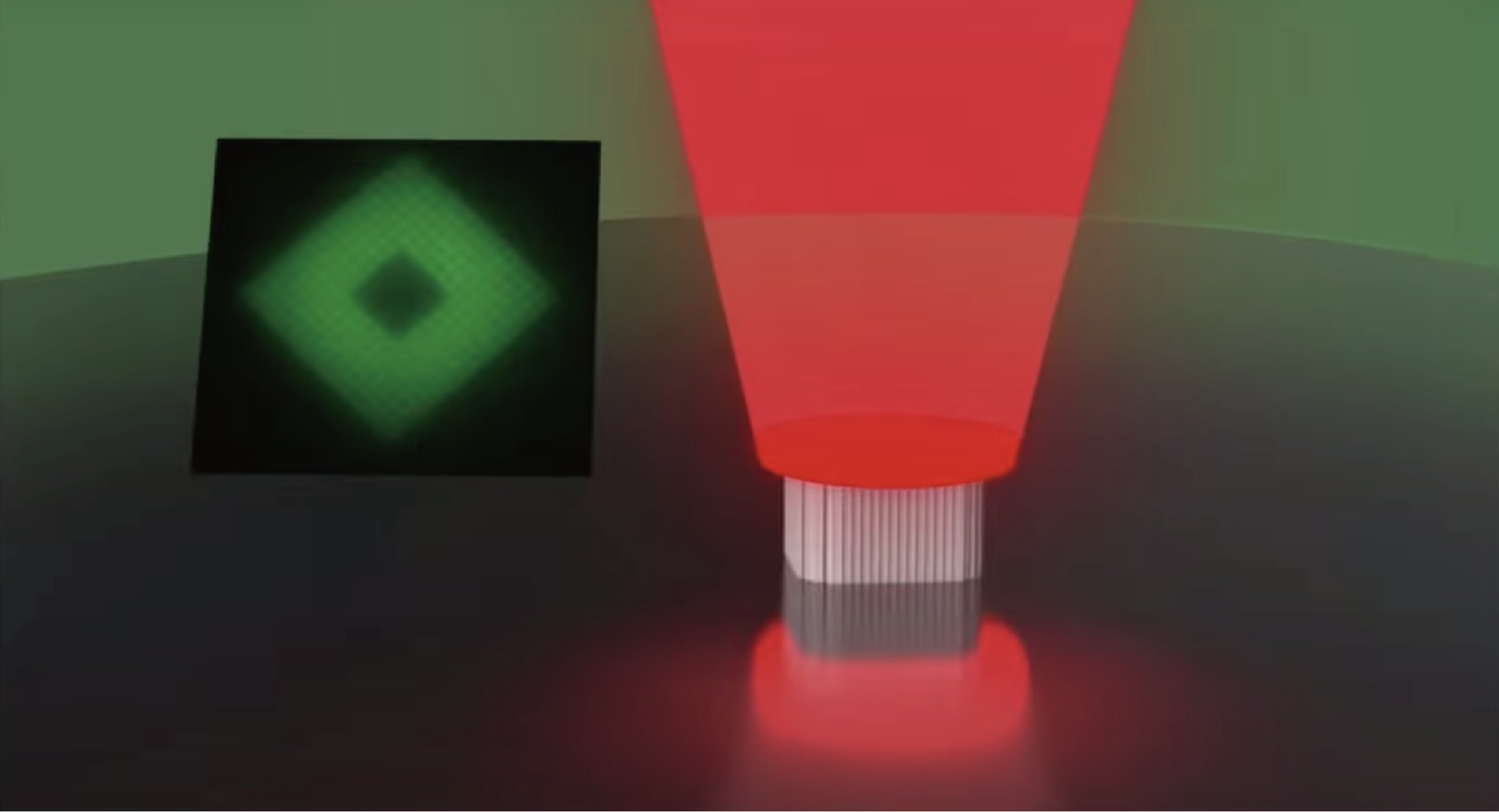

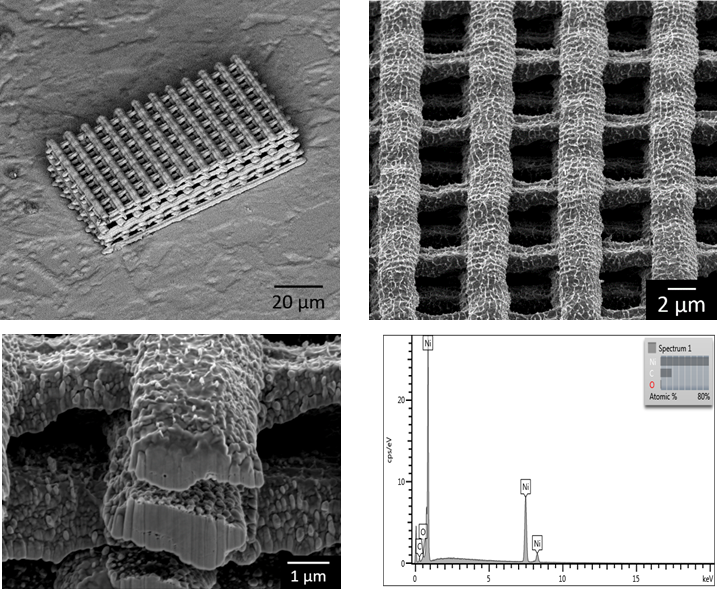

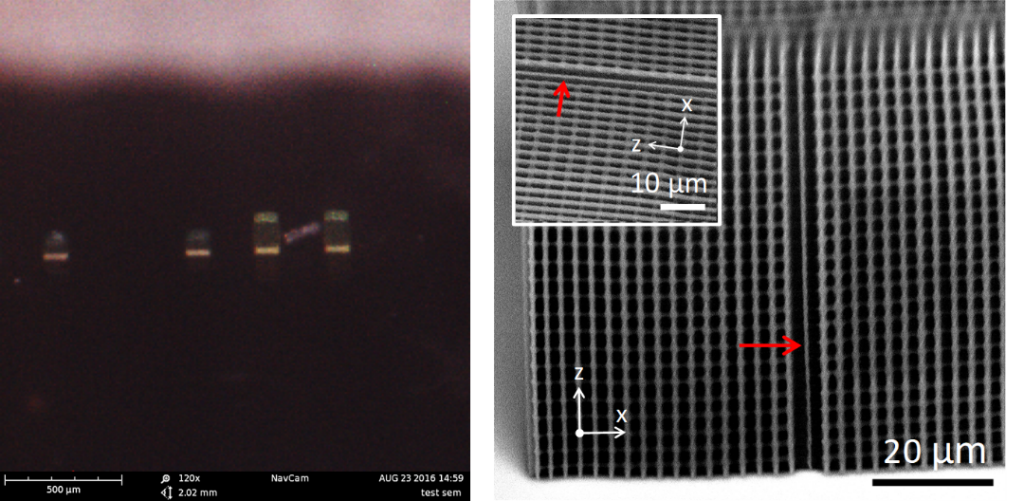

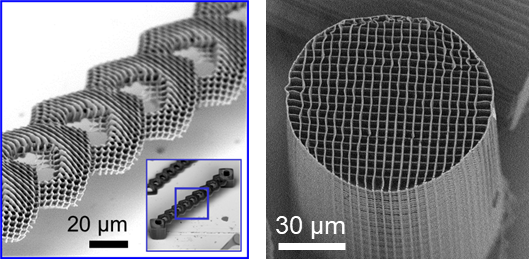

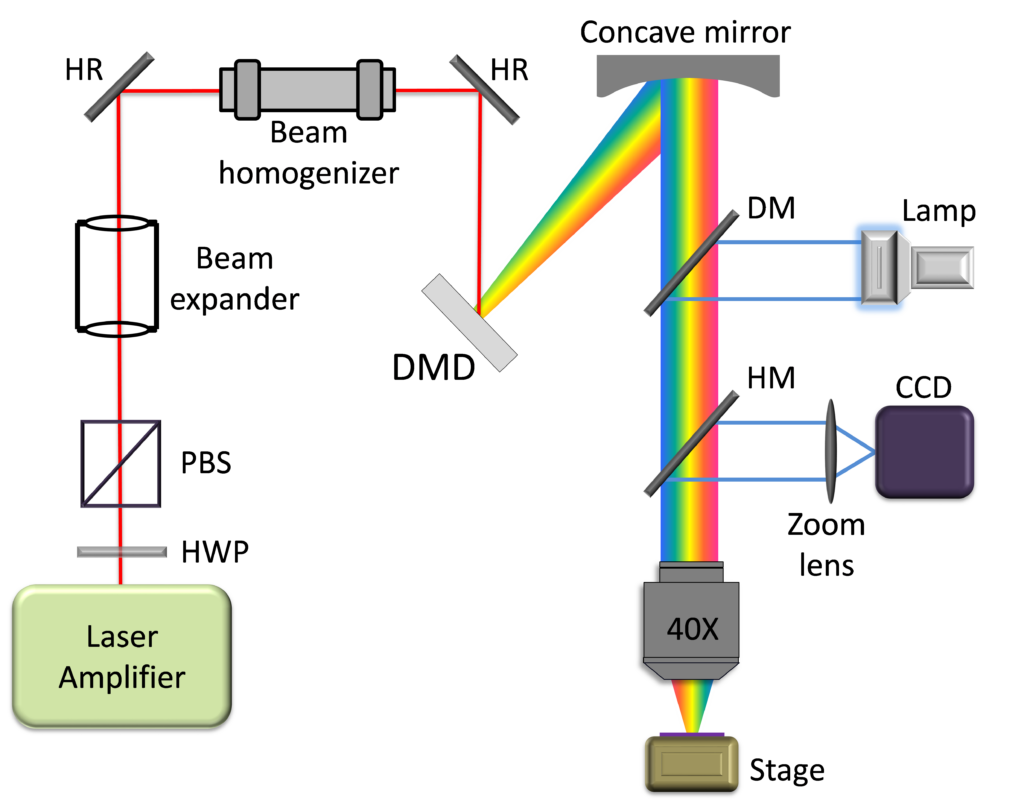

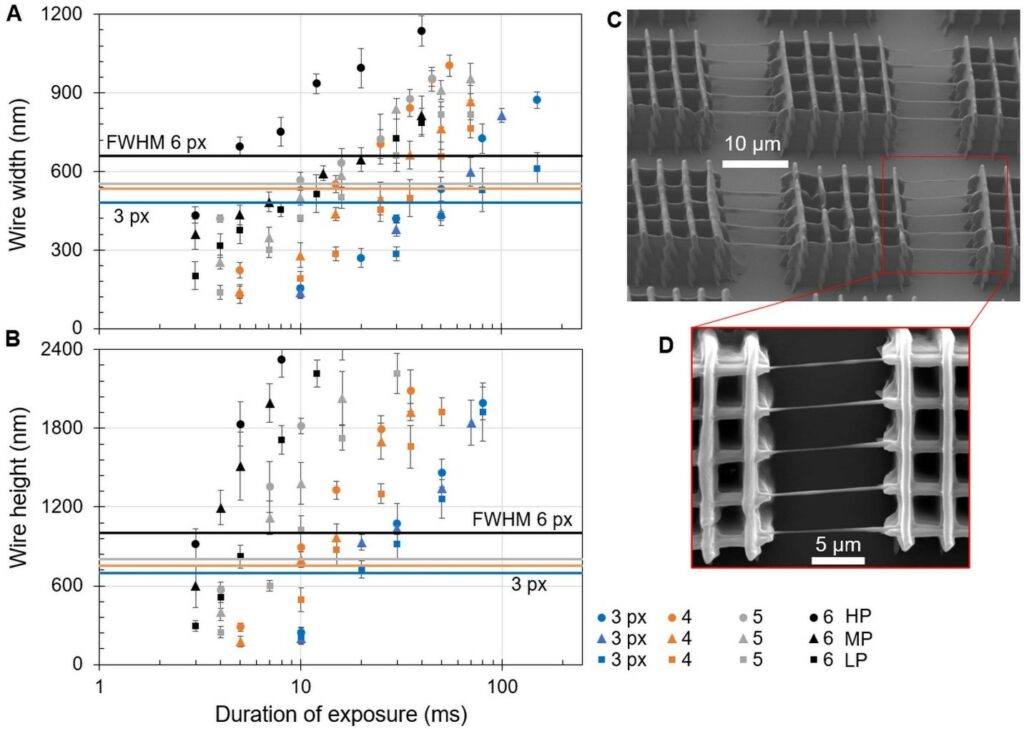

This project develops the “Femtosecond Projection Two-photon Lithography (FP-TPL)” printing technology, which overcomes the challenging problem by exploiting the concept of temporal focusing, where a programmable femtosecond light sheet is formed at the focal plane for parallel nano-writing; this is equivalent to simultaneously projecting millions of laser foci at the focal plane, replacing the traditional method of focusing and scanning laser at one point only. What makes FP-TPL a k/ technology is that it not only greatly improves the speed (approximately 10 – 100 mm3/hour), but also improves the resolution (~140 nm / 175 nm in the lateral and axial directions) and reduces the cost (US$1.5/mm3). This new technique substantially increases the printing speed by 1,000 – 10,000 times, and reduces the cost by 98%. Besides, due to the slow point-scanning process and lack of capability to print support structures, conventional TPP systems cannot fabricate large complex and overhanging structures. The FP-TPL technology has overcome this limitation by its high-printing speed, i.e., partially polymerised parts are rapidly joined before they can drift away in the liquid resin, which allows the fabrication of large-scale complex and overhanging structures.

FP-TPL technology can benefit many fields; for example, nanotechnology, advanced functional materials, micro-robotics, and medical and drug delivery devices. Because of its significantly increased speed and reduced costs, the FP-TPL technology has the potential to be commercialised and widely adopted in various fields in the future, fabricating meso- to large-scale devices.

Reference:

S.K. Saha, D. Wang, V.H. Nguyen, Y. Chang, J.S. Oakdale, S. Chen, “Scalable Submicrometer Additive Manufacturing,” Science, 366(6461):105-109, 2019.