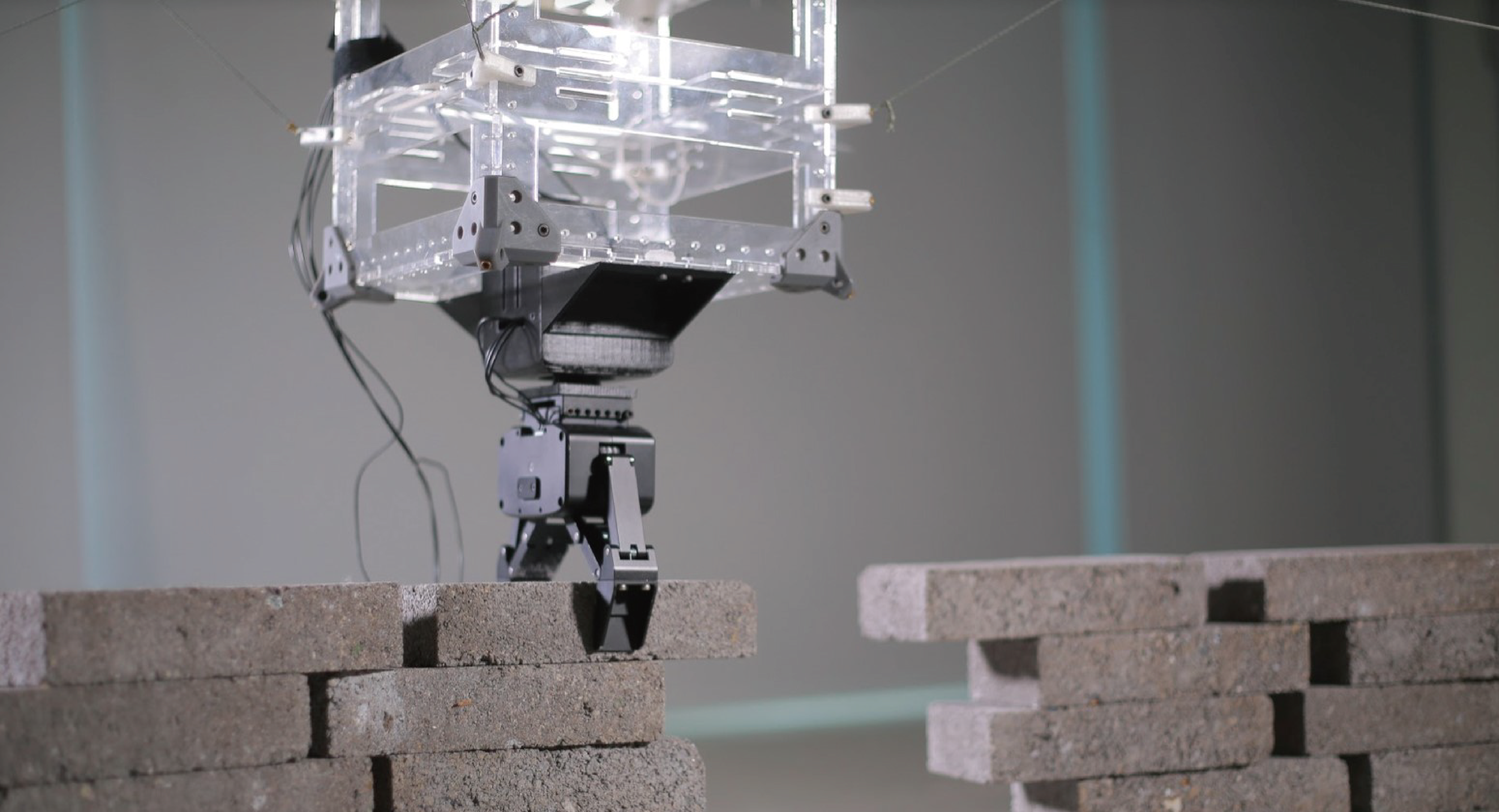

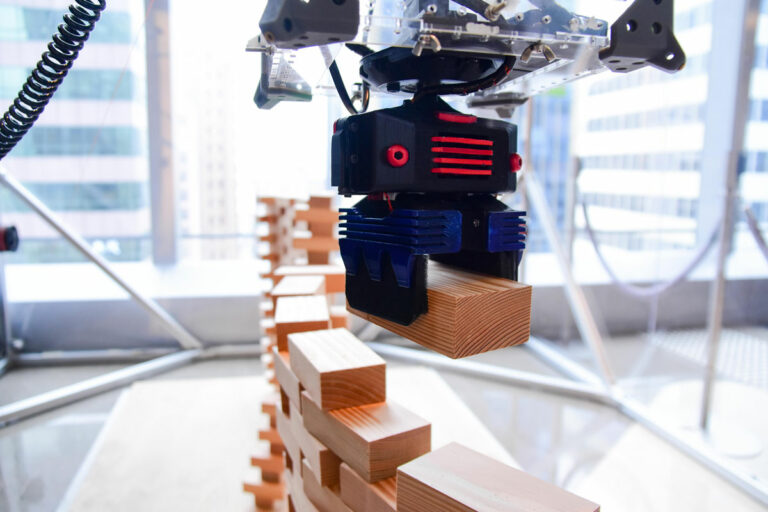

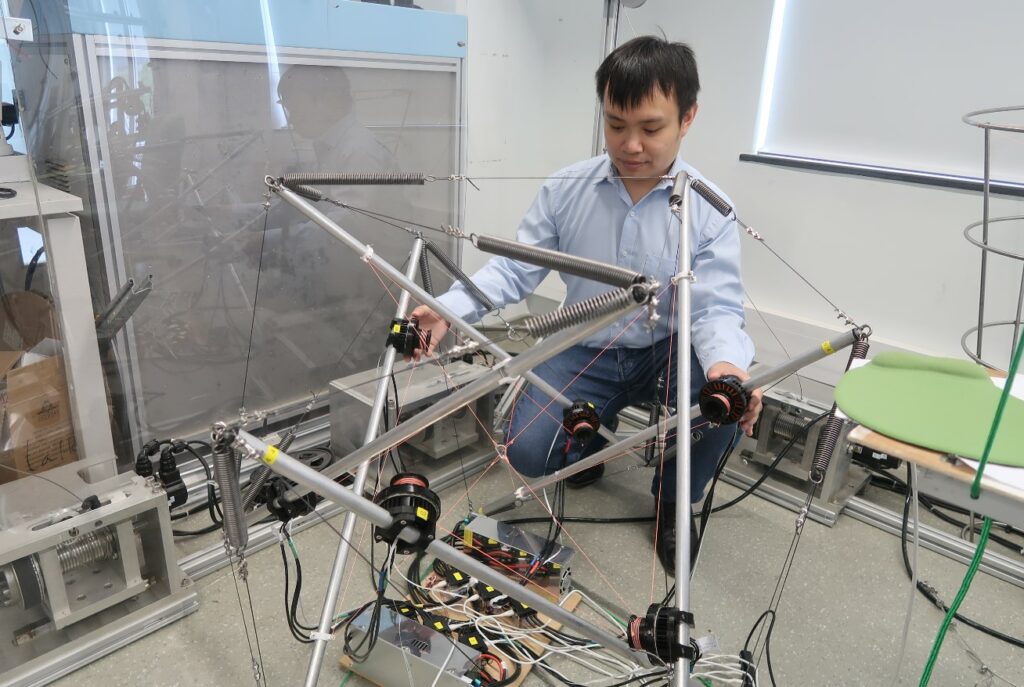

The “CU-Brick” system consists of a gripper end-effector and cable actuators which can be mounted on a range of different environments, from metal frame structures to the walls and roofs of buildings. The design is performed through developed intelligent software. The system will then automatically generate the structure to be built, while keeping the robot within the designated operational region and ensuring the number and location of bricks remain unchanged. It can turn innovative designs into executed complex brick placement operations. With the ability to work 24/7 and error-free, “CU-Brick” can perform the same task with higher precision and consistency compared to the current techniques which are constrained by several factors including building time and costs. It also better addresses the problems of labour costs and worker safety.

Uniqueness and Competitive Advantages:

- High portability and convenient setup

- Higher precision

- Can easily execute more complex designs with the same costs

- Different construction materials can be used, including wood, bricks and cement