Biodiesel is an emerging renewable fuel commonly used in blends with petroleum diesel, which produces less pollutants than traditional pure diesel. It is typically produced from cooking oil, in which requires rigorous pretreatment resulting in water pollution. Enzymes can also act as a catalyst to produce biodiesel. In fact, enzymes generate less waste and require lower temperatures than traditional base catalysts. Unfortunately, in their current state, enzymes are too expensive to compete with base catalysts. This is because enzymes require tedious purification procedures and subsequent immobilization to be easily recycled and reused.

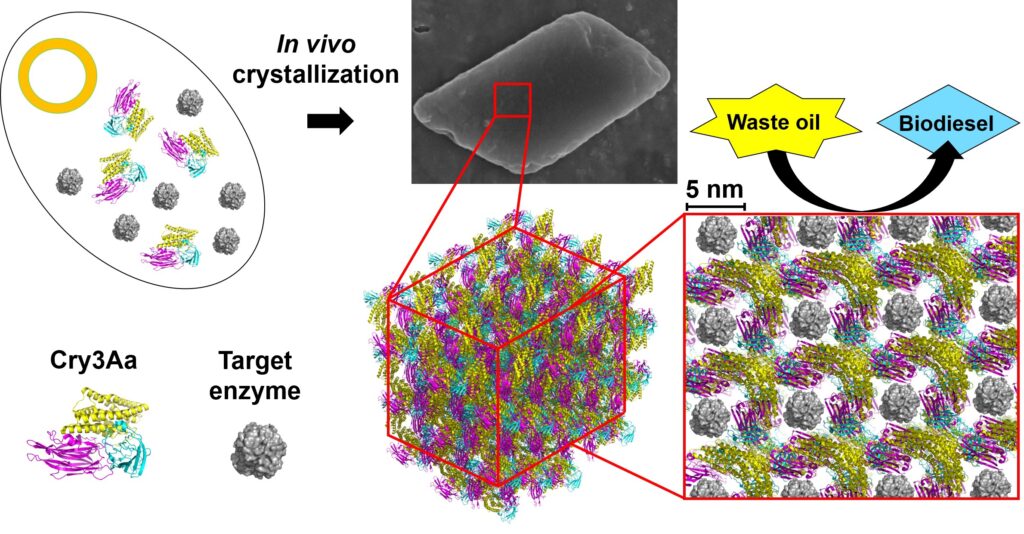

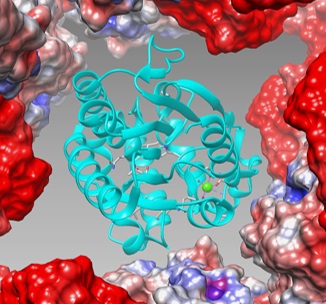

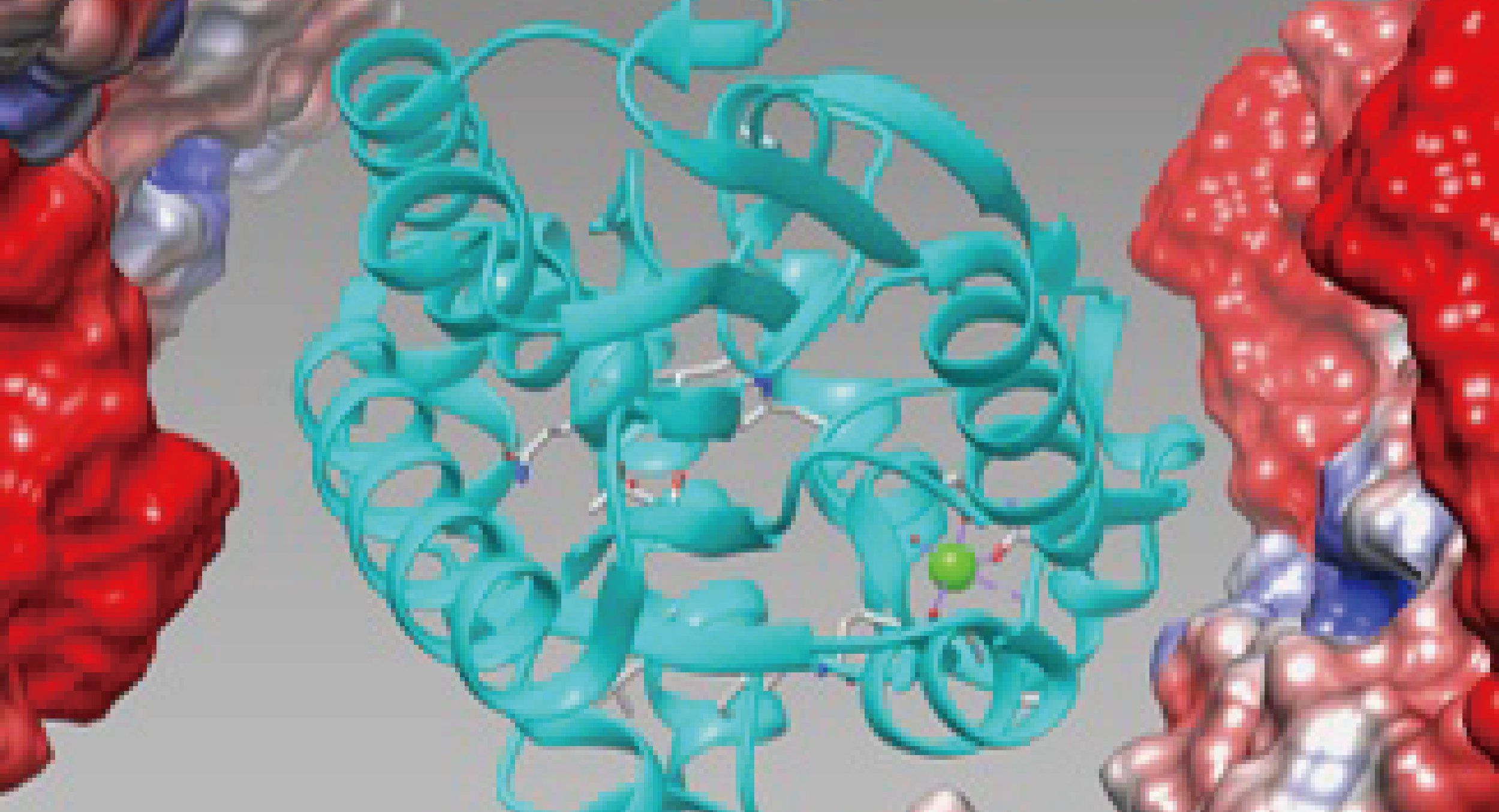

This project developed a novel method to overcome these hurdles. The approach involves trapping enzymes in protein crystals produced naturally in bacteria, and then isolating these crystals in a single step. This greatly simplifies the isolation procedure and reduces cost. When an enzyme and a special protein called Cry3Aa were produced together in the same bacteria cell, the resulting crystals contained millions of copies of the enzyme trapped inside the pores. These crystals could be easily isolated and applied to produce biodiesel. They found that entrapment of this enzyme inside the Cry3Aa crystals made it much more stable, allowing it to be used in multiple cycles of biodiesel production from waste cooking oil.