Machines used in rapid prototyping and light industry, such as 3D printing, cutting and engraving, typically operate in a smaller volume or area. This is due to the significant increase in complexity, weight and cost of larger systems, owing to the rigid links and actuation methods that are currently used. A laser cutter which operates only in one squaremeter costs several hundred thousand Hong Kong dollars; while it can only operate on a single planar surface.

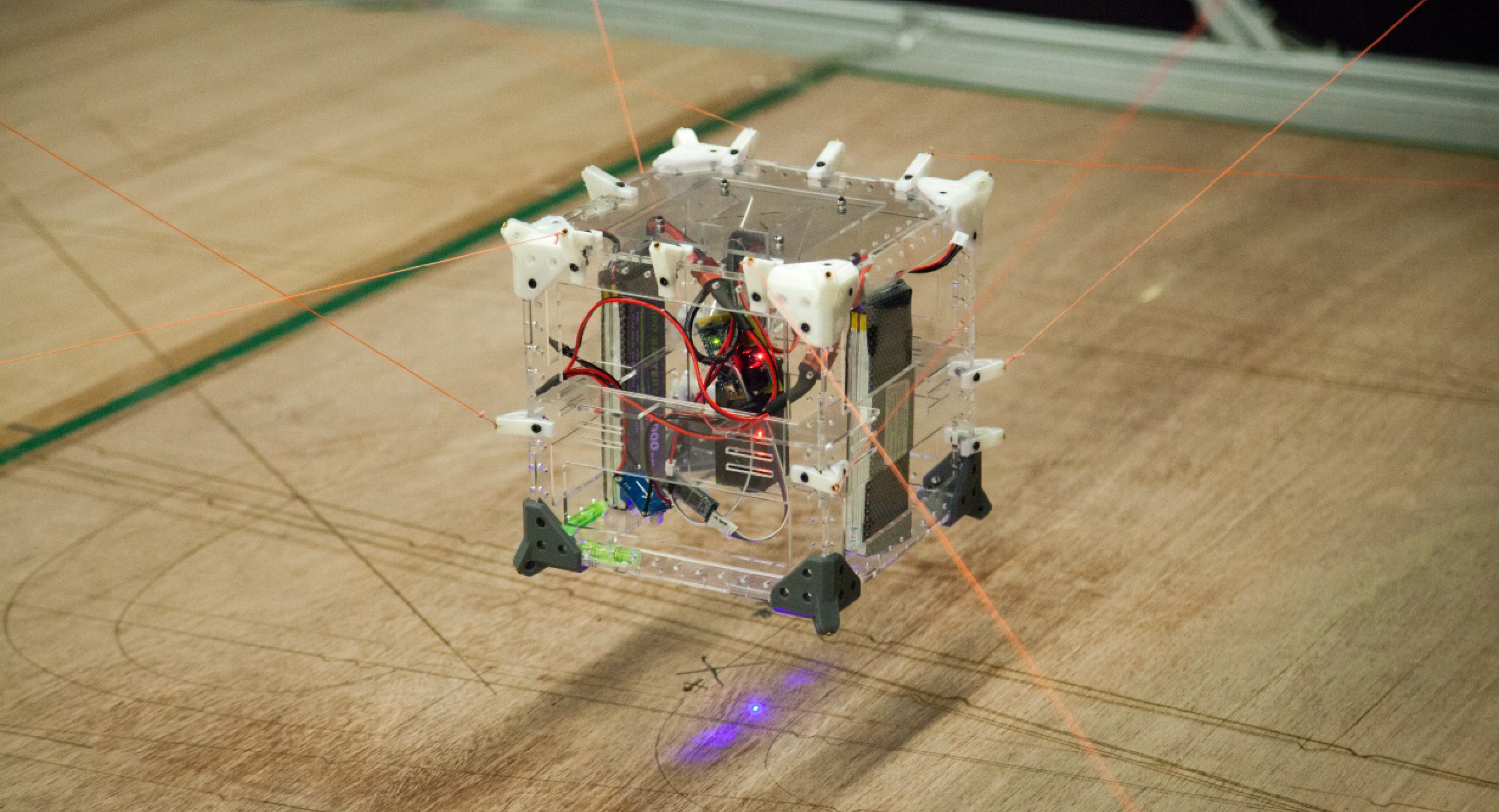

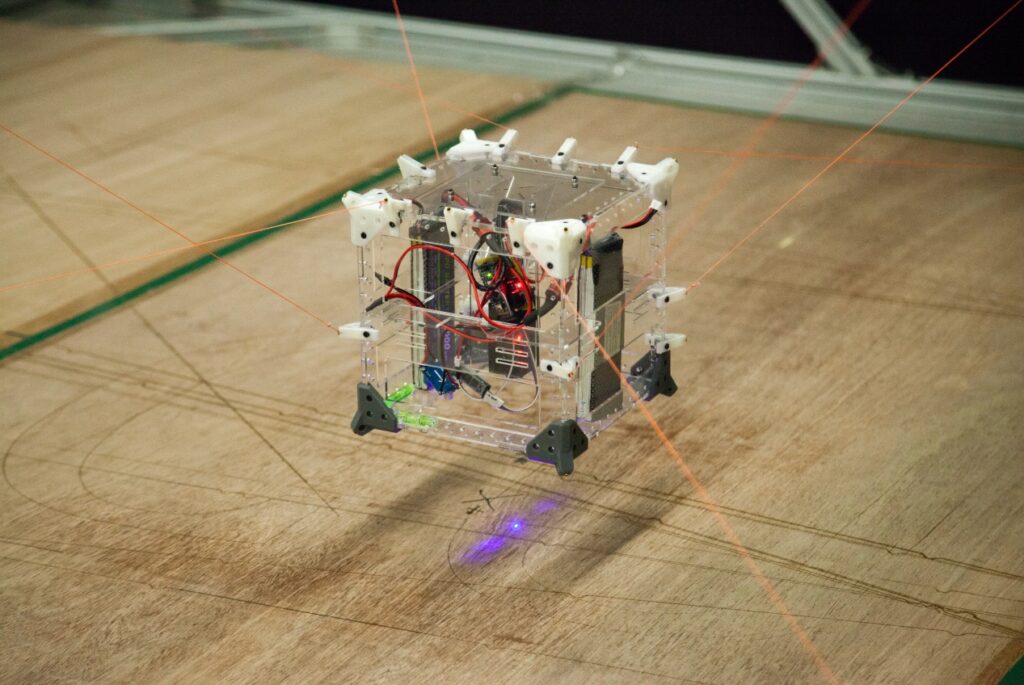

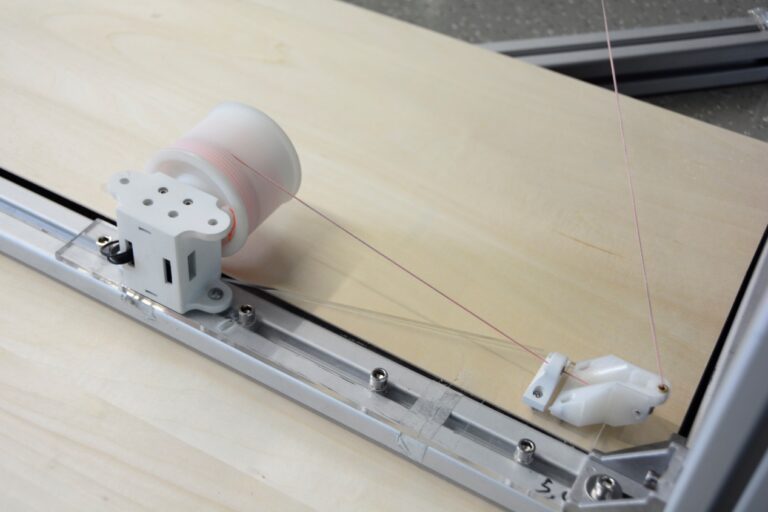

Our team has developed a cable-driven large-scale laser engraving and cutting robot that breaks through the above limitations. To achieve a light-weight, portable and large cutting area, the laser end-effector is moved through a set of cables connected to it in parallel. The developed 4m x 4m x 4m system shows its simplicity and expandability, where the cable actuators and end-effector can be deployed easily at different locations and with little limitation to its maximum size.

Uniqueness and Competitive Advantages:

- Very large operational volume

- Simple design and low cost

- Portable and easy to setup at any location

- Ability to operate in 3D

- Ability to replace the end-effector for different lasers or even other tools