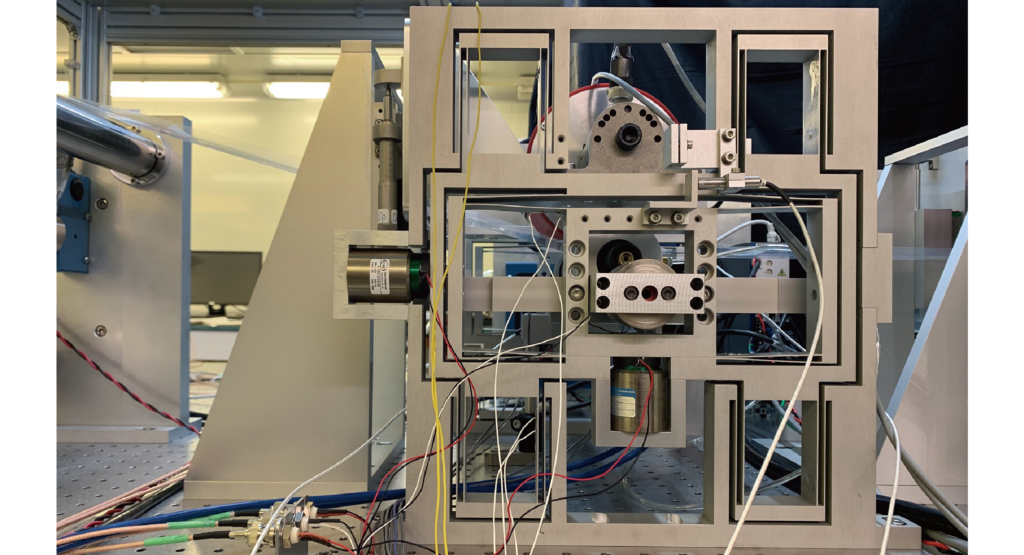

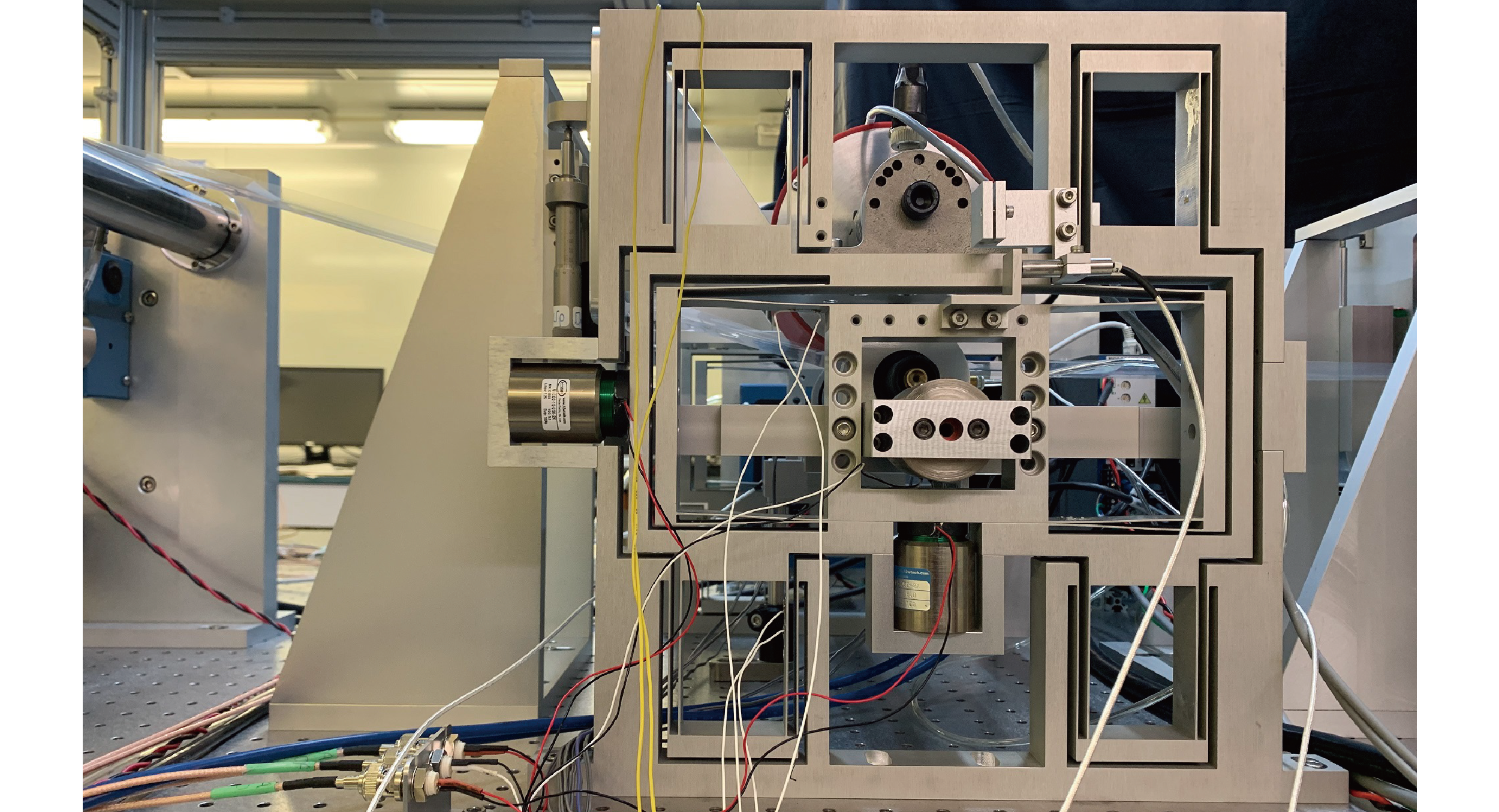

Positioning and robotic technologies are essential elements for large-scale automated manufacturing. However, the existing robotic platforms only allow robots to perform routine and simple assembly processes with low precision (100s µm – mm scale), which sensors applied in these platforms are very expensive. Combining deep learning with precision engineering principles to improve efficiency and accuracy, we develop next-generation precision machines and robotic platforms for low-cost, high-precision manufacturing.

Uniqueness and Competitive Advantages:

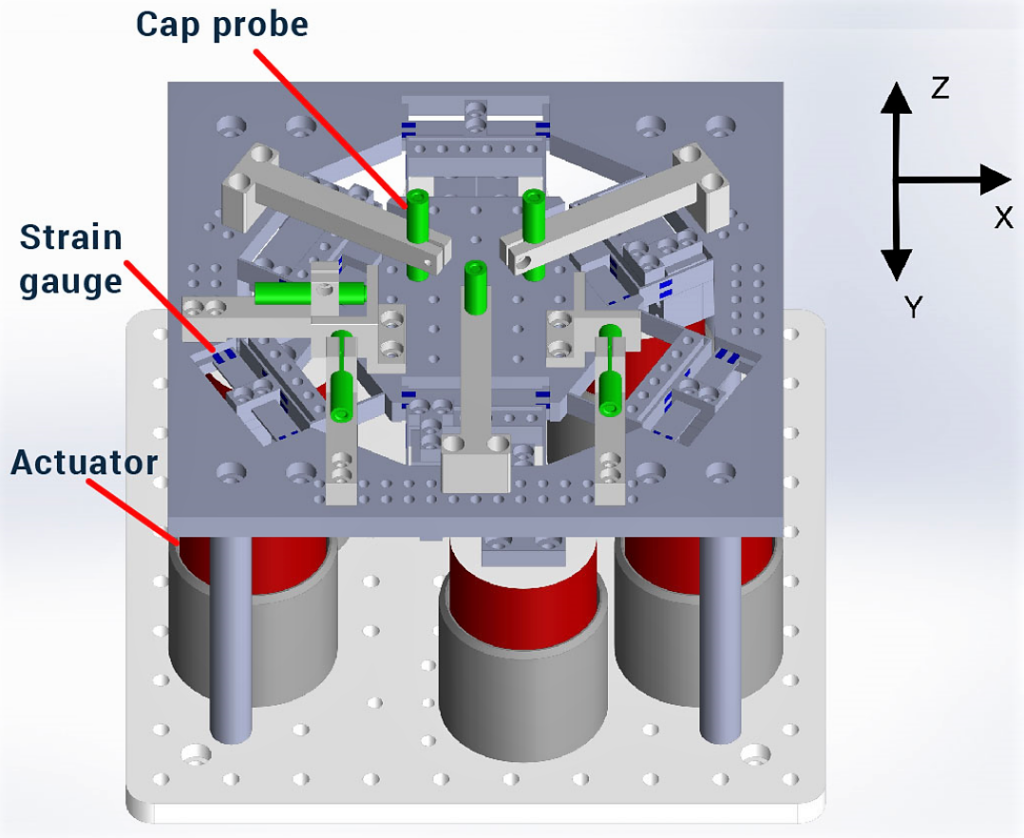

- We propose to use low-cost strain gauges to replace costly capacitance probes used in conventional systems.

- Deep learning algorithms enable learning and prediction of machine behavior. At the training stage, high-precision sensors are used as a reference to minimize position errors; while the number and location of sensor arrays and actuators are optimized through the deep learning model.

- Though effectively combining deterministic and statistical approaches, low-cost sensor arrays and actuators installed can predict machine behavior with 10s nm to submicron level precision.