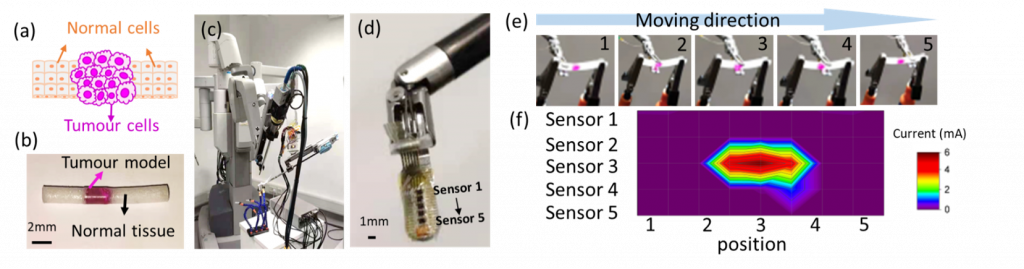

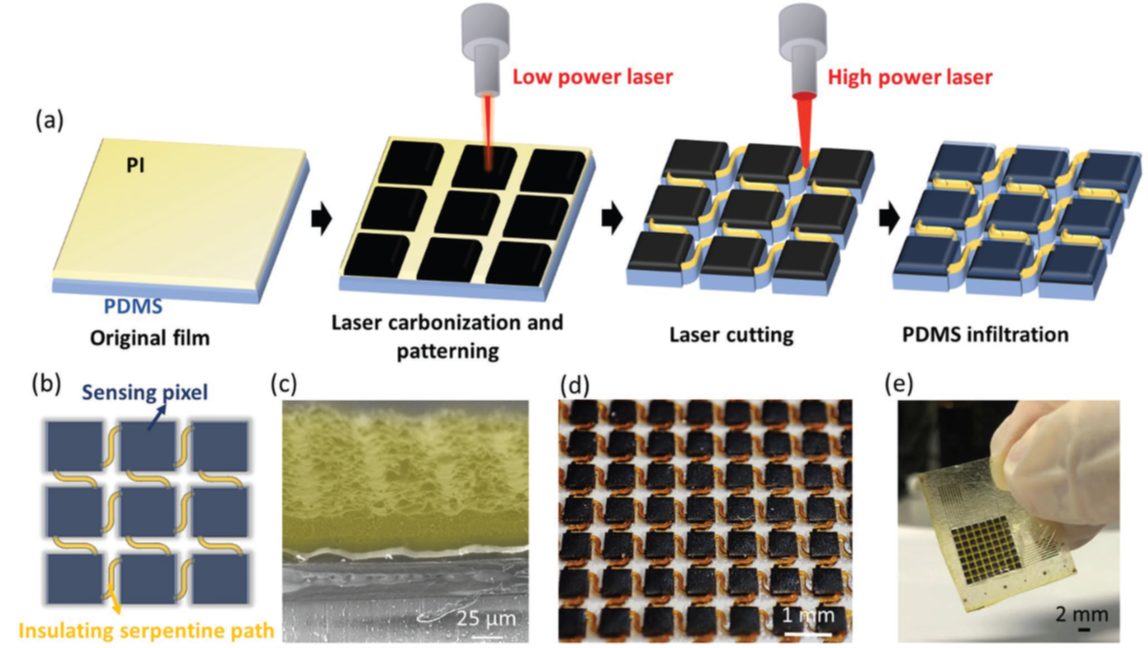

This project aims to develop a high-resolution flexible pressure sensor array through a two-step laser manufacturing process, where individual sensing pixels and their interconnects are sequentially defined by laser induced graphitization and ablation to minimize crosstalk interferences between sensor pixels. The geometry of the interconnects is optimized through theoretical modeling and experimental validation. Characterization results show that the new device design induces a remarkable reduction of the crosstalk coefficient, from −8.21 to −43.63 dB, of the 0.7 mm-resolution sensor arrays, and the crosstalk suppression is particularly beneficial for application scenarios involving pressure sensing on soft surfaces (e.g., human skin and organs). Applications of the sensor array in minimally-invasive cancer surgery is demonstrated.

Uniqueness and Competitive Advantages

• A two-step laser manufacturing method is introduced to address the crosstalk problem in pressure sensor arrays at low fabrication cost

• Through theoretical modeling and experimental validation, a serpentine interconnect design yields the best result, from −8.21 to −43.63 dB, greatly reducing the crosstalk between individual pixels

• Serpentine interconnect design is particularly beneficial for pressure mapping on soft surfaces (e.g. human skin and organs)

• An 8 × 8 sensor array with a high resolution of 0.7 mm is achieved, with individual pixels exhibiting a high sensitivity, a wide pressure working range, a fast response time and good cycle stability

• The sensor array can locate the tumor edge with approximate millimeter accuracy